STAINLESS-STEEL EXTRUSION

This specialty is the basis of the whole organization; on that note alone MNS KAMKIM has constantly upgraded and maintained its extrusion presses and auxiliaries to cater to the customized profile requirements made by our customers. We have 1460T, 1380T and 600T processes. We also pride our extrusion tolerance that is within tolerance of the standards of ISO 6362 and JIS H4100 or tighter tolerance upon discussion. Adhering to these standards is crucial as these are the fundamentals of being able to meet products of high quality.

STAINLESS-STEEL ANODIZING

We use performing additives for superior surface finishing and color at the 1st and 2nd step of the anodizing process. These Chemicals are non-toxic to the work force and the environment. Customers may also pick the colors of their choice based on the color chart that is provided. We also follow strict operating procedures to ensure that the right balance or chemicals are used; the optimum temperature is obtained and maintained and timed to perfection. All this is done to ensure the best results are achieved.

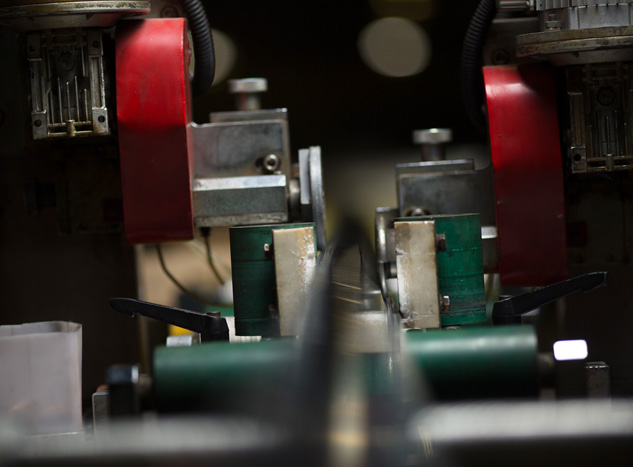

CUT TO LENGTH

Using German machinery, we are capable of producing clean cuts with precise length consistently. We have invested countless man hours, finances, training staff and procuring quality machinery so that this can translate to the promise that we make and keep to our customers; which is quality of the highest order possible.